UHV thin-film synthesis and characterization equipment overview

The following Thin-film deposition and characterization equipment is available at the Nanostructured Materials Research Unit:

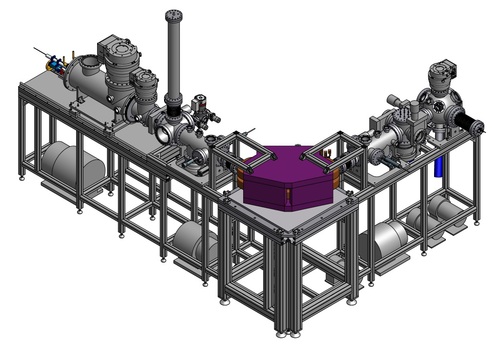

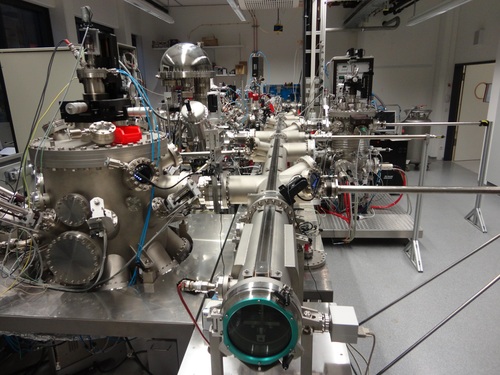

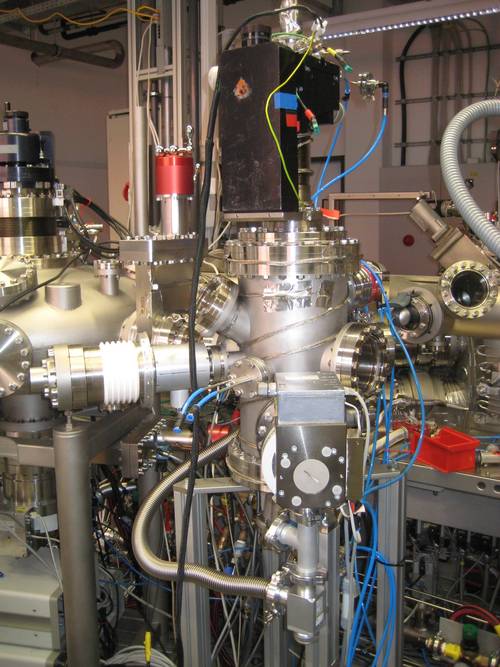

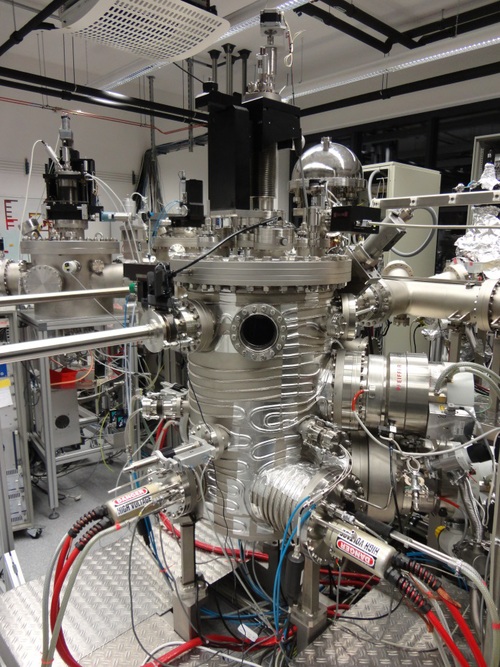

Equipment inter-connected by UHV transfer-line

The following equipment is inter-connected by a UHV transfer-line (see picture above), so that samples can be transferred in ultra-high-vacuum conditions. The system is equipped with two loadlocks: one for standard Omicron sample holders (Maximum sample size 11 mm x 11 mm) and the other for samples up to 2” in size.

1. UHV-Cluster Deposition System

Contact Person: Thomas Reisinger

Our home-built UHV-Cluster Deposition System provides a beam of mass-selected clusters for deposition purposes. The cluster size can be adjusted in a wide range from few atoms up to several thousands of atoms with a mass resolution between 1/50 and 1/10. Featuring additional evaporators for matrix materials and protective layers the whole range of cluster-based materials including Cluster-decorated surfaces, pure cluster thin films and various cluster-matrix combinations can be synthesized.

2. UHV Scanning-Probe Microscope

Model: Omicron VT AFM XA

Contact Person: Thomas Reisinger

The Omicron ultra-high vacuum scanning-probe microscope can be used to image surfaces with both scanning-tunneling microscopy and atomic-force microscopy techniques (both contact-mode and non-contact mode) without the influence of ambient air (oxygen, humidity). It is accessible via the load-lock for the small Omicron sample plates (maximum size 11 mm x 11 mm). Its base pressure is in the 1e-11 mbar range. The STM electronics feature the latest preamplifier technology for true sub-pA scanning tunnelling microscopy and spectroscopy. Stable low current operation is important for the investigation of surfaces that are sensitive or have a low conductivity. For modulation spectroscopy an electronic compensation reduces the influence of parasitic currents. This saves acquisition time and improves results. The classic Beam Deflection AFM for contact and non-contact AFM offers the flexibility for many operational modes and different cantilever types. For example high resolution AFM, Friction Force Microscopy, Electrostatic Force Microscopy (EFM), Scanning Kelvin Probe Microscopy (SKPM) and Magnetic Force Microscopy (MFM) are available.

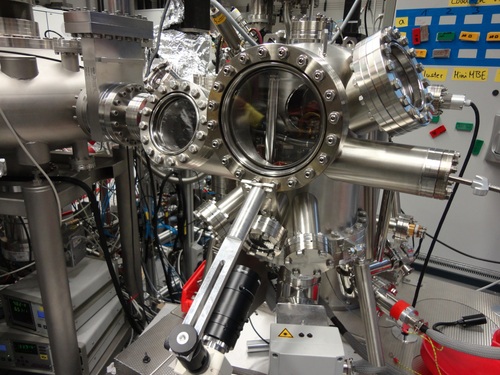

3. Mini Molecular-Beam Epitaxy

Contact Person: Robert Kruk

The MiniMBE system is meant for thin film deposition of expensive and very rare materials, including noble metals and isotopically enriched material for Mössbauer spectroscopy. The instrument is equipped with two four-pocket-Mini e-beam evaporation sources (Oxford applied research), which allow for very small evaporation rates from evaporation rods or small crucibles. A RHEED (Reflection High Energy Electron Diffraction) system allows for in-situ control/monitoring of the growth, the evaporation rate is monitored using two Quartz-Micro-Balance and the sample manipulator can be heated up to 800°C. Two turbomolecular pumps and one Ti-sublimation pump create a base pressure of < 1e-10 mBar. The MiniMBE chamber is connected with the integrated UHV system and further in-situ characterization of the samples by LEED, XPS and STM/AFM is possible.

4. X-ray Photo-electron Spectroscopy

Contact Person: Robert Kruk

X-Ray (XPS), UV (UPS) and Auger Electron Spectroscopy (AES) are techniques that allow for measurements of elemental composition and chemical states of material surfaces. The integrated Ultra High Vacuum (UHV) laboratory is equipped with the UHV analytic chamber comprising two X-Ray generators for low- and high resolution XPS; UPS, and AES analysis.

Sources:

Al/Mg dual anode

Al/Ag dual anode monochromator

UV source (helium)

Capabilities:

Ar ion gun for sputter cleaning of surface (up to 5kV)

Electron flood gun for charge neutralization

X-Ray Energy: 10-14kV for Al/Mg sources

Analyzer:

PHOIBOS 150, <1eV resolution

Nine channeltron array detector

5. Pulsed-Laser Deposition

Contact Person: Alan Molinari

The PLD system is currently being constructed at Surface systems + technology GmbH & Co. KG. After the expected delivery in the middle of 2014, it will enable the deposition of complex oxide thin film heterostructures. Comprising an infrared-laser heated manipilator (up to 1000 °C), a 5× 1” target revolver, a Coherent CompexPro 205 KrF excimer laser and a differentially pumped RHEED system for in-situ analysis. As part of the interconnected UHV equipment, this tool will complete the portfolio of available thin film deposition systems.

6. Createc Magnetron-sputter deposition system

Model: Createc Fischer

Contact Person: Alan Molinari and Ralf Witte

Description:

The sputtering deposition system is equipped with eight 3"- magnetrons (La0.65Sr0.35MnO3, La0.5Sr0.5MnO3, La0.5Sr0.5CoO3, BiFeO3, PbZr0.52TiO3, In2SnO3, NiFe and W), which are arranged in an octagonal geometry, with the sample being positioned at the center in an on-axis geometry. Three Direct Current (DC) and two Radio Frequency (RF) power supplies are available to be attached at any of the eight magnetrons, allowing for the growth of sequentially or co-sputtered metal and oxide thin film systems.

The heatable infrared heated sample manipulator allows for substrate heating up to 850 °C, monitored by a thermocouple. To ensure a uniform distribution of heat and deposited material, the manipulator can be rotated up to 20 rpm.

A unique selling point of this so called Large-Distance Magnetron Sputtering (LDMS) system can be found in the uncommonly high target-substrate separation of 285 mm, which works around the issue of the oxygen ion bombardment against the substrate and the growing oxide thin film (due to the DC-bias field between the target and the chamber), guaranteeing at the same time homogeneous deposition and so high uniform thickness distribution even on large substrates. Thus, the LDMS system is able to produce high quality metal and oxide thin films.

7. Molecular-beam Epitaxy (MBE)

Model: Custom made (VAbVakuum: chamber, CreatecFischer: parts, shutter controller, Telemark: power supply)

Contact Person: Alan Molinari

Description:

The Molecular Beam Epitaxy (MBE) system is equipped with 3 electromagnetically focused electron beam evaporators. Each of them has its own electron beam deflection, emission current control, and thickness monitor unit. The sources are charged with Fe, Pd, Cr, Ti, Ag (source 1), Cu, Mg, Au (source 2) and Sc (source 3), giving the possibility of synthesizing thin film alloys (by co-deposition from different sources) and multilayers (by alternate evaporation). The system has a base pressure of 10-10 mbar.

Atomic Layer Deposition

Model: Picosun SUNALE R-200 Advanced

Contact: Ben Breitung

Description:

This is a full-fledged research ALD system, featuring a hot wall reactor for temperatures of up to 500°C, an ozone generator, a plasma generator, 3 liquid and 3 solid precursors. The latter can be heated up to 300°C. A bubbler option for low vapor pressure precursors is available. The "Picoflow" mode allows for coating of highly irregular surfaces with large high-aspect ratios (HAR) of up to 2000. A powder holder enables coating of micropowders.

In view of process control, the device is equipped with a quartz crystal microbalance (QCM) and a quadrupole mass spectrometer (QMS) for residual gas analysis (RGA). Sensitive samples can be handled in an argon glove-box and loaded into the process chamber through a load-lock.

The list of thin film materials that can be deposited includes (but is not limited to): Al2O3 and AlN, TiO2 and TiN, TaN, HfO2, ZrO2, SiO2, MgO, Ag and SnO.

Being attached to an argon glove-box, the ALD system can be employed for coating even delicate materials, such as battery electrodes.

Magnetron-Sputter System

The DC Sputtering System, built by Thermionics Inc. uses two sputtering guns (3” targets). The deposition chamber is connected with the UHV load lock chamber and RF sputtering system. Argon is used as a working gas, with O2 for reactive sputtering. Gun power supply has a limit of 500W. Target-substrate distance can be adjusted as well as the working pressure, power and gas flow.