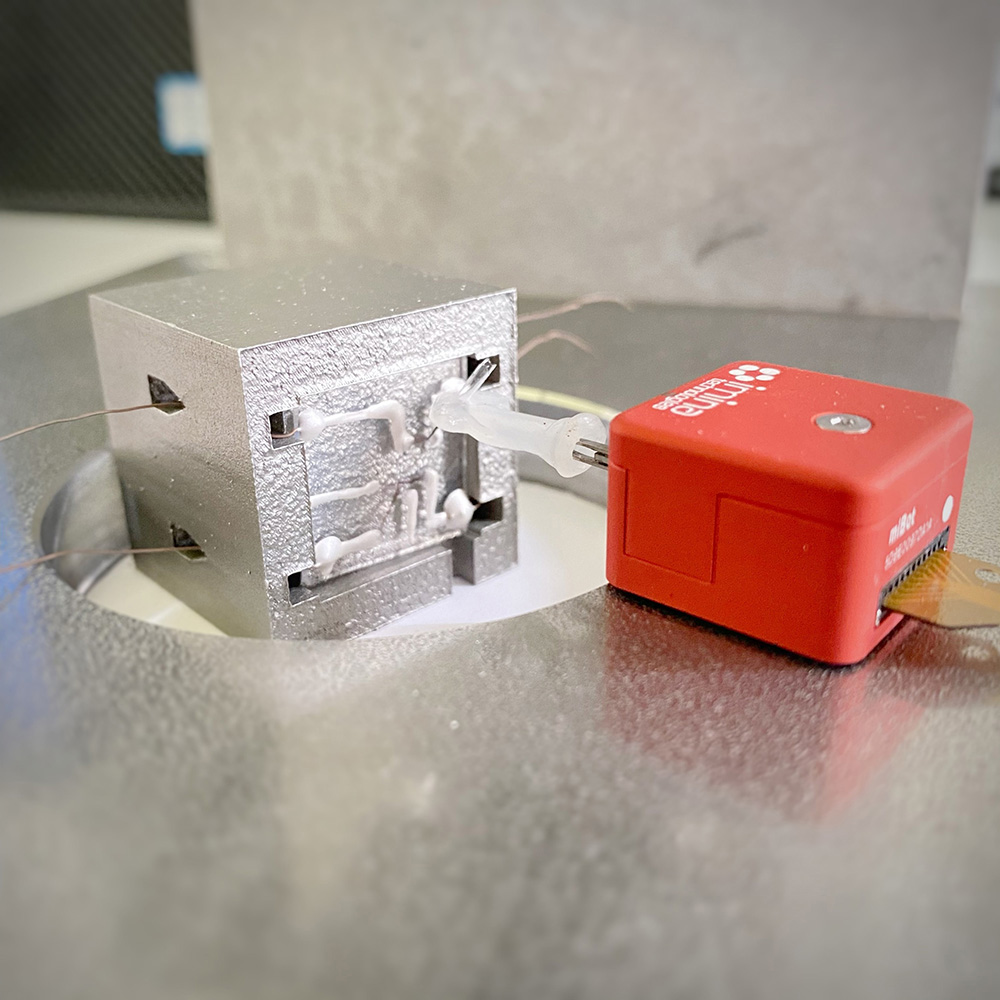

High-precision tabletop microplotter for flexible on-demand material deposition in printed electronics and device functionalization

-

Author:

N. Hussain, M. jan Nazami, C. Ma, M. Hirtz

-

Source:

Rev. Sci. Instrum. 92 (2021) 125104

- Date: 2021

-

Microstructuring, in particular, the additive functionalization of surfaces with, e.g., conductive or bioactive materials plays a crucial role in many applications in sensing or printed electronics. Mostly, the lithography steps are made prior to assembling functionalized surfaces into the desired places of use within a bigger device as a microfluidic channel or an electronic casing. However, when this is not possible, most lithography techniques struggle with access to recessed or inclined/vertical surfaces for geometrical reasons. In particular, for “on-the-fly” printing aiming to add microstructures to already existing devices on demand and maybe even for one-time trials, e.g., in prototyping, a flexible “micropencil” allowing for direct write under direct manual control and on arbitrarily positioned surfaces would be highly desirable. Here, we present a highly flexible, micromanipulator-based setup for capillary printing of conductive and biomaterial ink formulations that can address a wide range of geometries as exemplified on vertical, recessed surfaces and stacked 3D scaffolds as models for hard to access surfaces. A wide range of feature sizes from tens to hundreds of micrometer can be obtained by the choice of capillary sizes and the on-demand in situ writing capabilities are demonstrated with completion of a circuit structure by gold line interconnects deposited with the setup.