Thermal stability of ultrafined grain CuZn alloy processed by HPT

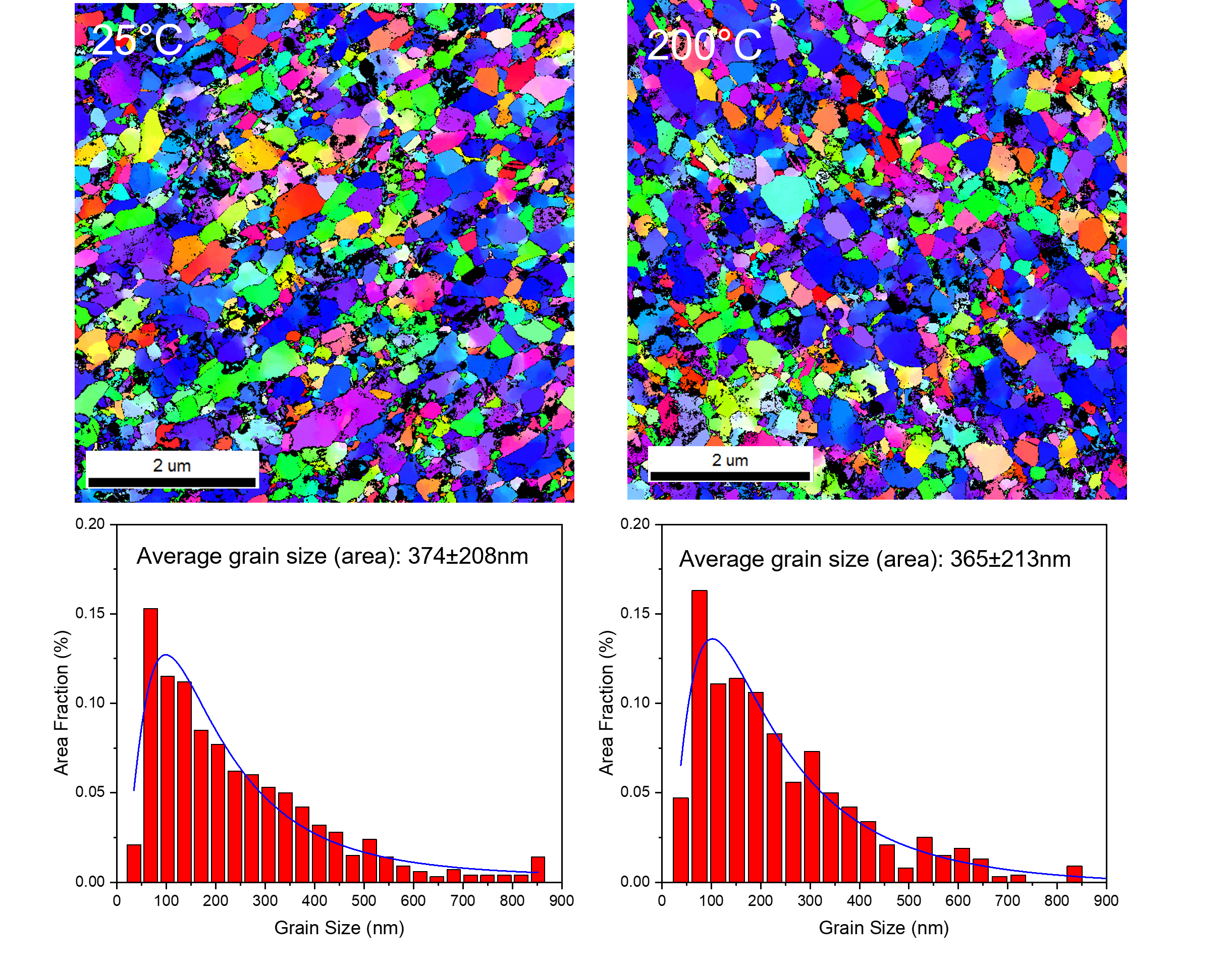

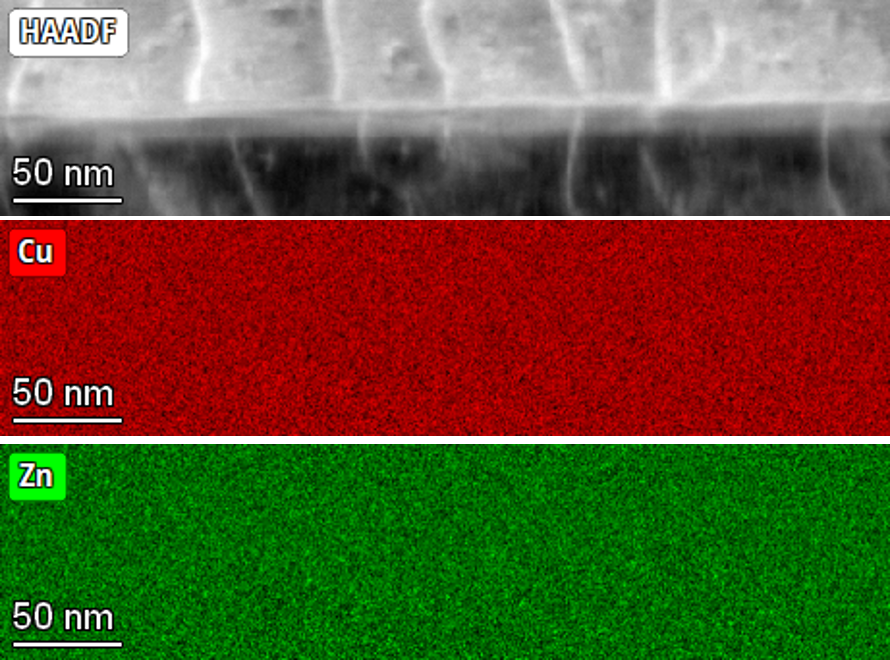

Ultrafine-grained and nanocrystalline copper-based alloys processed by severe plastic deformation offer a compelling framework for elucidating the interplay between grain boundary structure, solute chemistry, and thermal stability in highly refined metallic systems. In the case of Cu–5 wt.% Sn, high-pressure torsion (HPT) imposes extreme shear strain that transforms the initially coarse-grained material into a nanocrystalline structure with a very high grain boundary density, substantial lattice distortion, and elevated stored deformation energy, resulting in a pronounced increase in hardness. While such microstructures in pure copper are intrinsically unstable and susceptible to rapid grain growth even at low temperatures, the addition of tin fundamentally modifies the annealing response through boundary-specific solute segregation. Advanced characterization combining scanning transmission electron microscopy, energy-dispersive X-ray spectroscopy, and 4D-STEM orientation mapping demonstrates that Sn atoms preferentially segregate to general high-angle grain boundaries, whereas low-angle boundaries and Σ3 coincidence-site-lattice twin boundaries exhibit little to no enrichment. This selective segregation lowers the energy and mobility of high-angle grain boundaries, suppressing boundary migration and thereby stabilizing the ultrafine-grained structure during annealing up to intermediate temperatures.

As a consequence, short-time annealing does not lead to the expected softening associated with recovery or recrystallization; instead, it produces annealing-induced hardening, driven primarily by grain boundary relaxation and solute-stabilized interfaces rather than further grain refinement or precipitation. The stability of the grain size and the absence of secondary phase formation during this regime indicate that the hardening mechanism is governed by interfacial processes, including reduced dislocation emission from relaxed, solute-decorated boundaries and the elimination of energetically unfavorable boundary configurations. At higher annealing temperatures, the onset of grain growth reduces the fraction of high-angle grain boundaries, weakening the segregation-driven stabilization and promoting partial redistribution of Sn back into the grain interior, as reflected by changes in lattice parameter and a gradual decrease in hardness.

These observations underscore that thermal stability and mechanical performance in ultrafine-grained metals cannot be understood solely in terms of grain size, but must be interpreted through the combined effects of grain boundary character, chemical segregation, and boundary relaxation. The CuSn5 system thus provides a clear demonstration of how targeted solute–boundary interactions can be exploited to enhance the thermal reliability and mechanical robustness of nanostructured alloys without relying on complex multiphase microstructures, offering valuable guidance for the design of stable ultrafine-grained materials for advanced structural applications.

Details and further work are published at:

- Dai, Y., Ahmadian, A., Petry, O., Sos, M., Schwotzer, M., Durst, K., & Kübel, C. (2025). Microstructural evolution and mechanical properties of CuSn5 processed by high‑pressure torsion followed by short‑time annealing. Materials & Design, 259, 114897. https://doi.org/10.1016/j.matdes.2025.114897

Ultrafine-Grained Al–Mg–Si Alloys

Ultrafine-grained aluminum alloys produced through severe plastic deformation offer an effective pathway to overcome the long-standing compromise between mechanical strength and electrical conductivity, a limitation that is particularly critical for conductor-grade materials.

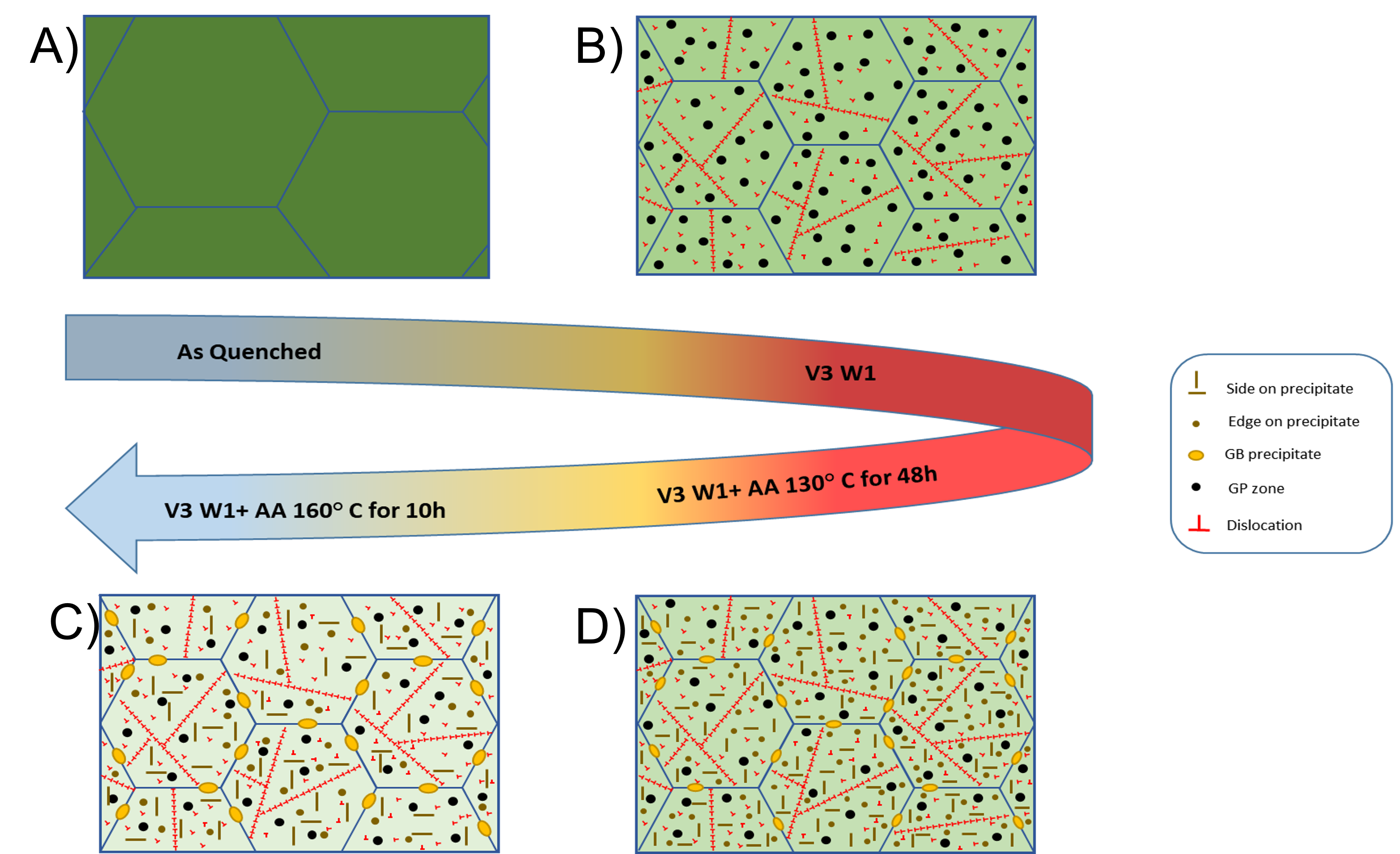

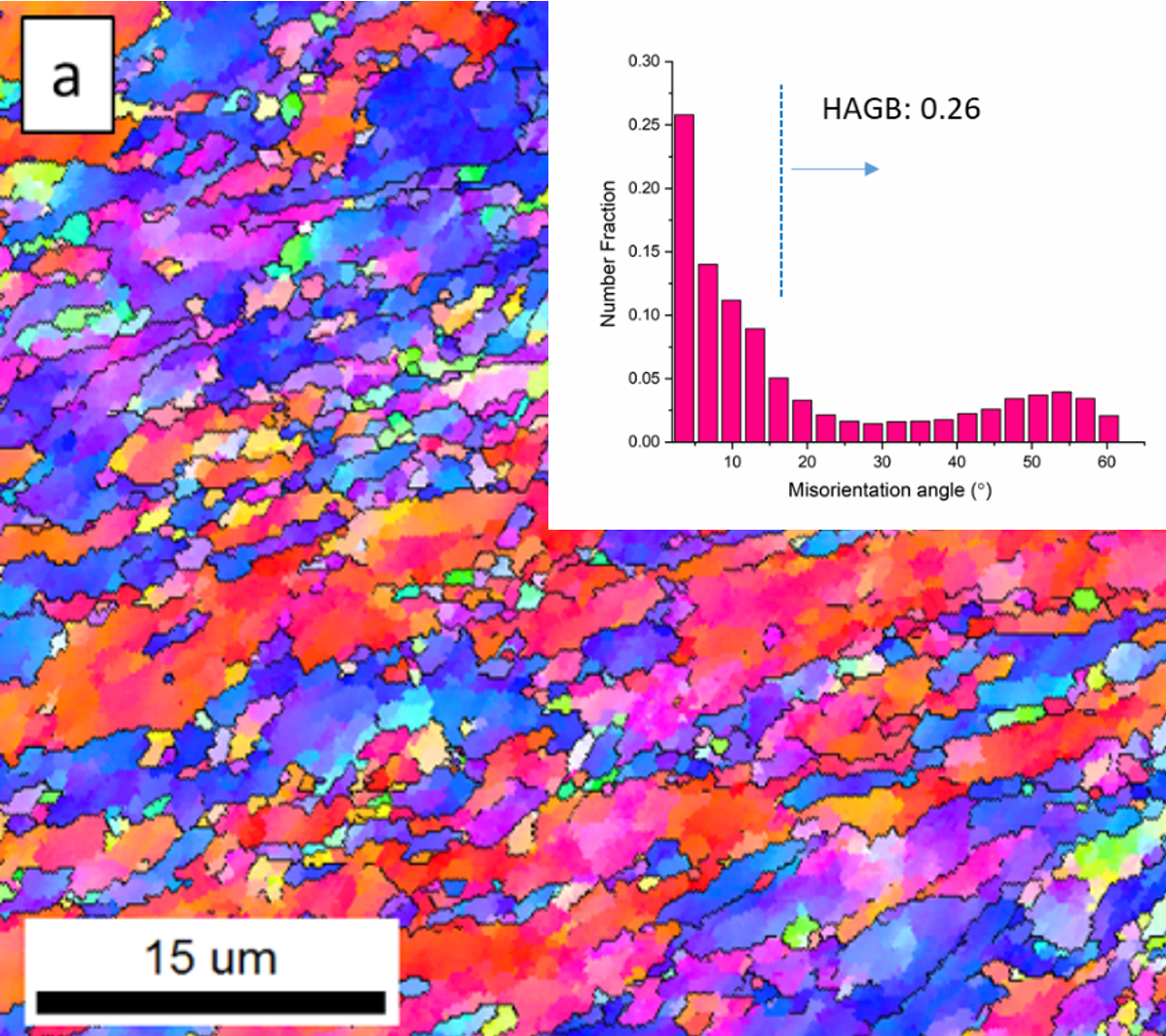

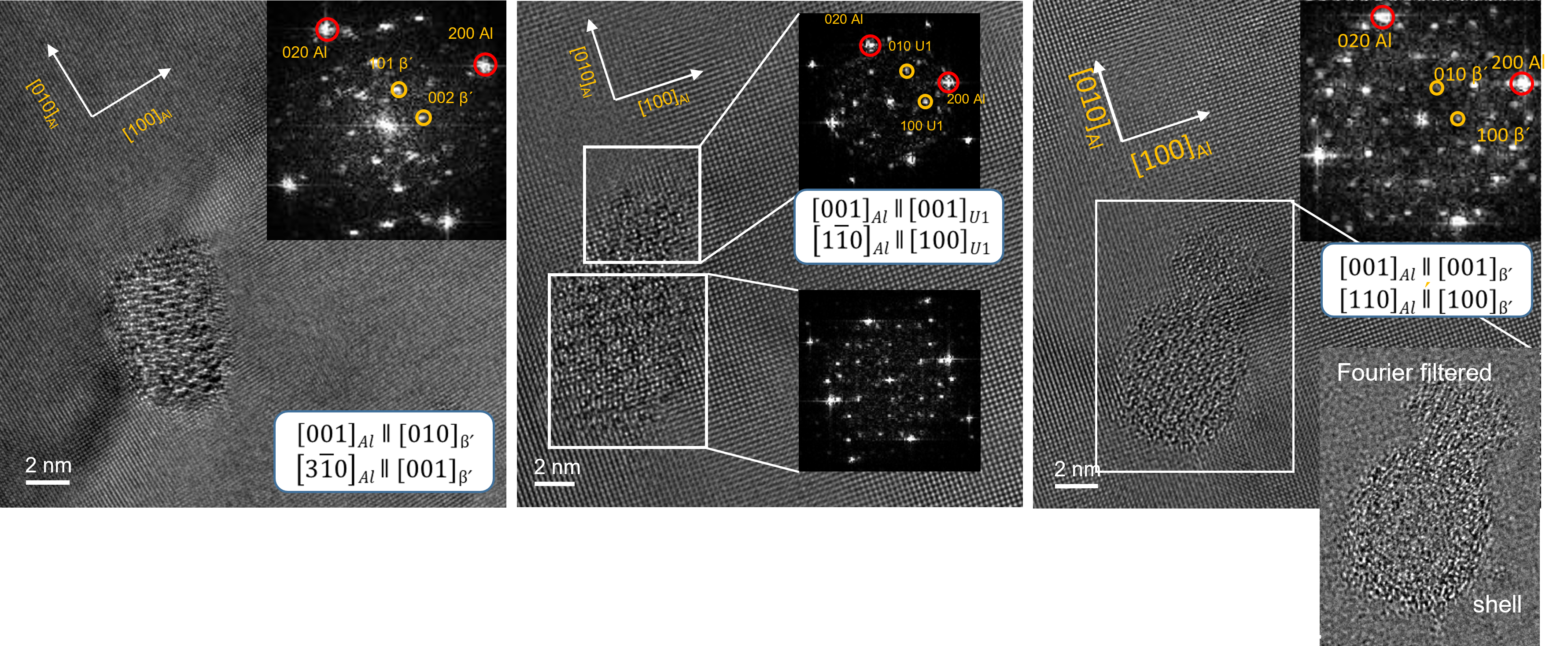

In Al–Mg–Si alloys, high-pressure torsion extrusion (HPTE) enables the development of a highly refined microstructure featuring elevated dislocation densities, subgrain formation, and pronounced lattice distortion, while remaining compatible with industrially relevant rod geometries. This deformation-induced defect structure stores substantial strain energy and provides fast diffusion pathways for solute atoms, which become decisive during subsequent thermal treatment. In the as-deformed condition, the alloy primarily contains Guinier–Preston (GP) zones—coherent solute clusters that contribute to strengthening but strongly scatter charge carriers and thus limit conductivity. Controlled artificial aging at moderate temperatures (130–160 °C) drives the transformation of these GP zones into a dense population of nanoscale Mg–Si–based precipitates that are uniformly distributed within the grains.

These intragranular precipitates significantly enhance mechanical strength by impeding dislocation motion, while simultaneously improving electrical conductivity by extracting Mg and Si atoms from the aluminum solid solution and thereby reducing electron scattering. The retention of a high dislocation density after aging further accelerates solute redistribution without promoting excessive grain growth, enabling efficient matrix purification. Although grain-boundary precipitation and the formation of precipitate-free zones influence ductility, their impact on the overall strength–conductivity balance is secondary compared to the dominant role of finely dispersed intragranular precipitates. Together, the interaction between ultrafine grains, deformation-induced defects, and controlled nanoscale precipitation establishes a robust microstructural design framework through which Al–Mg–Si alloys can achieve a combination of high strength and high electrical conductivity that exceeds conventional processing limits, positioning HPTE-based routes as a compelling solution for advanced aluminum conductor applications.

Details and further work are published at:

- Tavakkoli, V., Boltynjuk, E., Scherer, T., Mazilkin, A., Ivanisenko, Y., Ungár, T., & Kübel, C. (2024). Precipitate-mediated enhancement of mechanical and electrical properties in HPTE-processed Al–Mg–Si alloy. Materials Science and Engineering: A, 906, 146556. https://doi.org/10.1016/j.msea.2024.146556

- Tavakkoli, V., Brauch, L., Boltynjuk, E., Scherer, T., Mazilkin, A., Eusterholz, M., Boll, T., Ivanisenko, Y., & Kübel, C. (2025). Atomic resolution analysis of precipitates formed in an HPTE deformed Al‑Mg‑Si alloy. Materials Science and Engineering A, 923, 147704. https://doi.org/10.1016/j.msea.2024.147704