Porous Materials

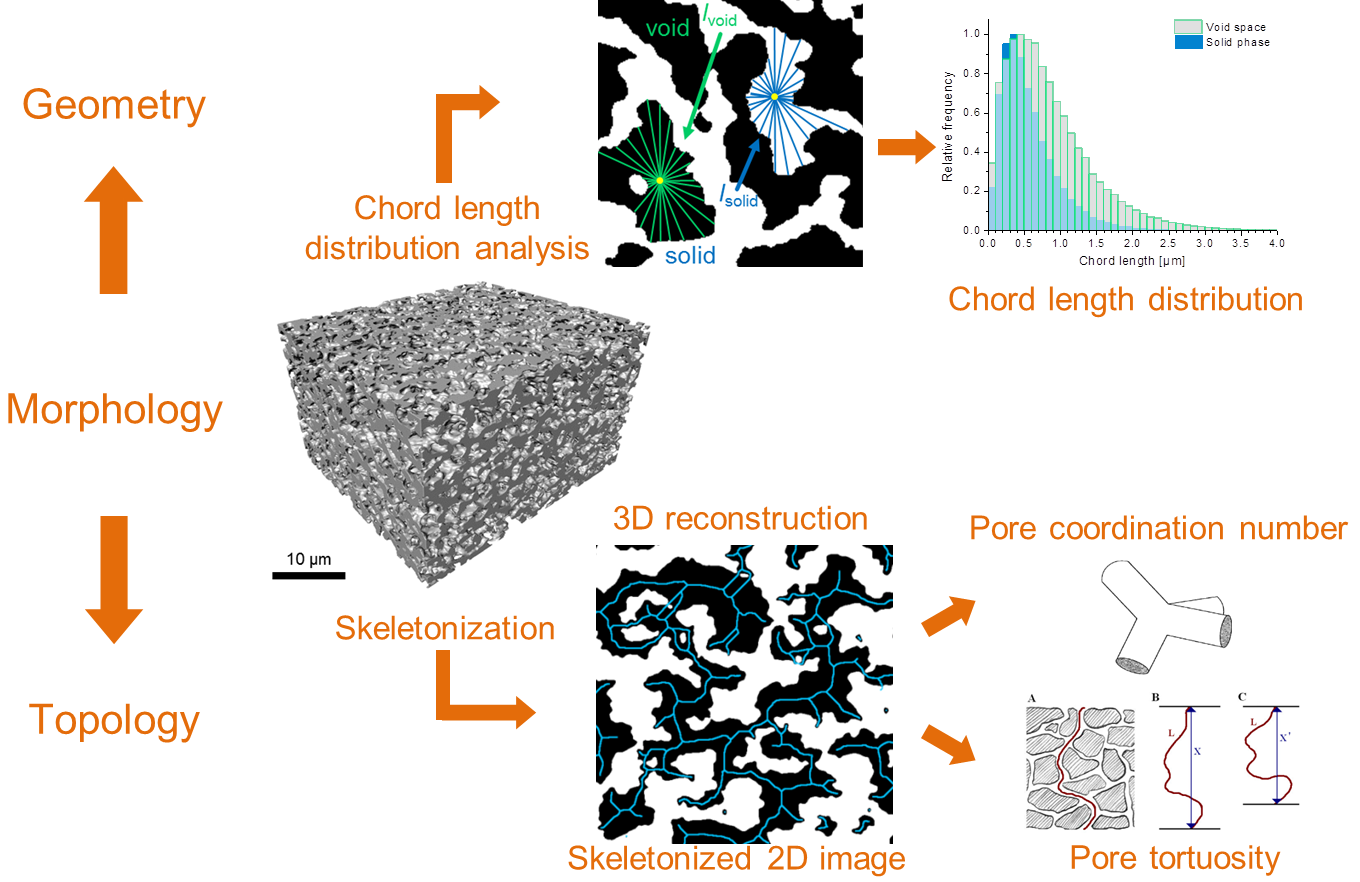

As an example for a quantitative analysis of interconnected structures, we have been working in close collaboration with Prof. Ulrich Tallareks group at the University Marburg, Dr. Katja Schladitz at Fraunhofer ITWM and Dr. Alberto Villa group at the University Milano on describing the morphology of porous media across length scales from the nanometer to the micron level quantitatively by characterizing both the topology and the geometry based on segmented FIB slice&view tomography and (S)TEM tomography data as illustrated in Fig. 1. Whereas classical bulk characterization techniques such as small angle X-ray scattering or N2/Hg porometry require a model to analyze the pore structure, this approach provides directly interpretable information while covering statistically significant volumes. In fact, this approach be used to develop models for an analysis using bulk techniques.

Figure 1: Schematic illustration of the quantitative analysis of porous materials (courtesy Dr. Daniela Stöckel, University Marburg)

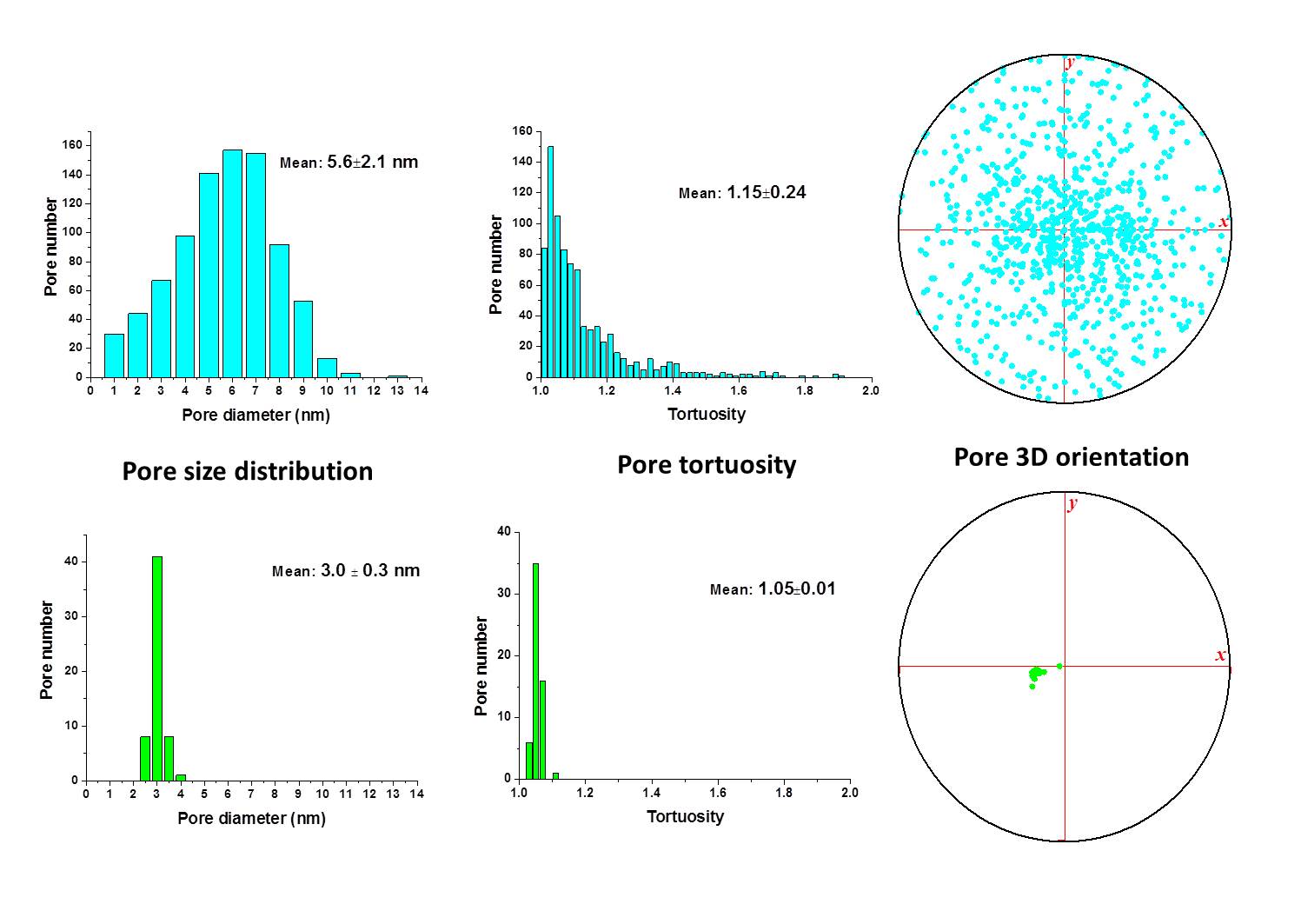

Application areas for the research include separation media such as silica monolith used in HPLC, where we could correlate the average pore diameter in these disordered materials with the structural uniformity (Fig. 2) and catalysis, where the pore structure (Fig. 3) is influencing the catalytic performance and selectivity.

Figure 7: Quantitative analysis of a series of FIB slice&view tomography reconstructions of silica monoliths with different pore sizes: The order parameter k is uniform when the average pore diameter (represented by the mean chord length) is larger than ~ 1 um, but decreases rapidly for smaller average pore sizes.

|

|

|

|

|

Figure 8: Segmented 3D reconstruction of a disordered and an ordered mesoporous carbon with a quantitative analysis of the pore size distributionand, the tortuosity and the pore orientation (pole figure) providing a quantitative description of the visually intuitive differences between the materials.

D. Stoeckel, C. Kübel, M. Loeh, B. Smarsly, U. Tallarek, Langmuir, 2015, 31(26), 7391–7400; DOI: 10.1021/la5046018.